Maximum flexibility and continuous further development guarantee you a sustainable investment in the future.

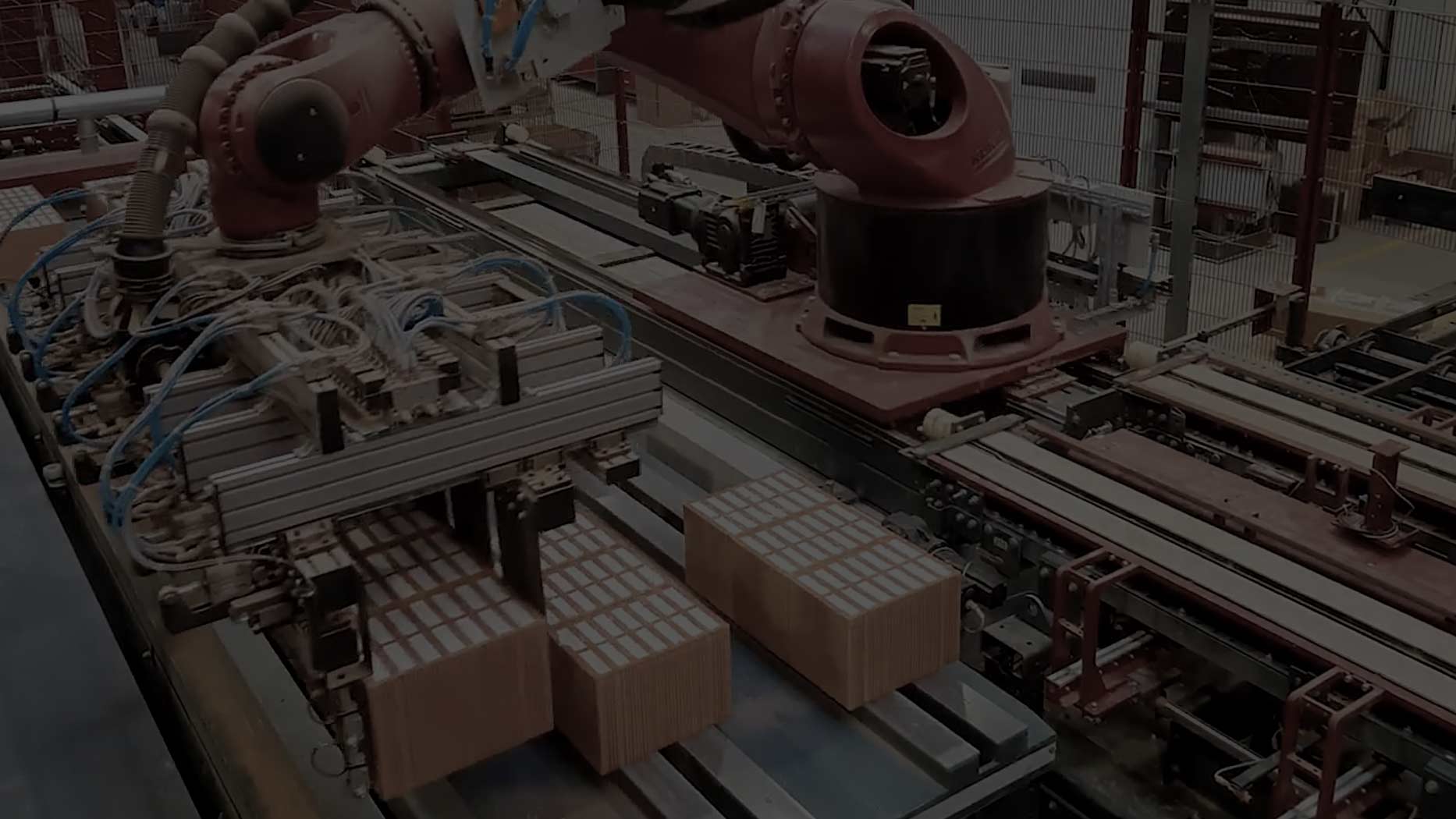

For the industrial production of wall elements made of mineral building materials such as brick, aerated concrete, sand-lime brick, Redblocsystems GmbH supplies the complete turnkey production line including CAD/CAM software through to ERP merchandise management software, the installation of the system and the training of your staff.

With our systems, several hundred square metres of wall elements can be produced per day. Assembly on site is fast and efficient. An entire storey can be erected within a few hours. Even our transport and lifting system can be reused for the next deployment.

The production of roof slopes, window and door openings or other geometric elements as well as the increase of the vertical range of manufacture by producing installation ducts or socket outlets is seamlessly integrated into the process. Industrial production counteracts the shortage of skilled workers and at the same time reduces the complaint rate. In addition, less time on site also means less downtime due to weather conditions and thus a plannable and rapid completion of your projects.

Our production lines are available in three different versions (Rebloc Basic, Redbloc Economic, Redbloc Advanced), which are designed according to your needs - from semi-automatic to fully automatic. Due to the modular design of our lines, a later upgrade is also possible without any problems.

Redbloc Basic

Block material: brick, aerated concrete, cement blocks, pumice blocks, wood cement blocks and other mineral building materials

Processable block formats:

Height = 120 - 300 mm,

Lenght = 125 - 625 mm,

Width = 100 - 510 mm

Maximum wall length: 6,000 mm

Maximum wall height: 3,500 mm

Production output: 100 – 120 m² per 8 h shift

(depending on available formats and house design)

The Redbloc Basic system type requires whole formats for the respective wall thickness. Half formats and fitting pieces are cut offline by means of a diamond circular saw. The layers are set using weight-balanced vacuum grippers. All other subsequent processing steps - such as drilling of the lever-off holes, setting of the layers, adhesive application and circulating pallet transport - are carried out fully automatically. Due to the modular design of our production lines, this kind of line can be upgraded to a Redbloc Economic or Redbloc Advanced line at any time.

Redbloc Economic

Block material: brick, aerated concrete, cement blocks, pumice blocks, wood cement blocks and other mineral building materials

Processable block formats:

Height = 120 - 300 mm,

Lenght = 125 - 625 mm,

Width = 100 - 510 mm

Maximum wall length: 6,000 mm

Maximum wall height: 3,500 mm

Production output: 250 – 350 m² per 8 h shift

(depending on available formats and house design)

The fully automatic Redbloc Economic production line requires half and whole formats for the respective wall thickness. The conceptual approach of this line is based on the production of so-called "grid walls" with a fixed overbinding dimension of 50 %. Preferably, the building materials used already have the vertical lift-off holes necessary for the reusable lift-off system. The trimming to the actually necessary dimensions is done in this system in the finishing centre. Here we offer various systems - wire saw, water jet system or milling centres.

Redbloc Advanced

Block material: filled and/or not filled brick, aerated concrete, cement blocks, pumice blocks, wood cement blocks and other mineral building materials

Processable block formats:

Height = 120 - 300 mm,

Lenght = 125 - 625 mm,

Width = 100 - 510 mm

Maximum wall length: 6,000 mm

Maximum wall height: 3,500 mm

Production output: 200 – 350 m² per 8 h shift

(depending on available formats and house design)

The Redbloc Advanced plant type was specially developed for the use of filled building materials. In this system, beginners and fitting pieces are cut exactly to size so that there are no open cuts at the wall ends or at window reveals. With this type of system, the lever holes are also drilled fully automatically, depending on the automatically calculated centre of gravity. Due to the design, half-formats are not absolutely necessary with this type of system.

Redblocsystems - movie about 3 production lines

- Redbloc Basic

- Redbloc Economic

- Redbloc Advanced

Loading this source will conntect to external server which use cookie and tracking technologies. Further information can be found in our privacy policy.